In this article, we take a closer look at piezometers, instruments used to measure water pressure underground. They are essential in engineering projects where accurate subsurface monitoring is crucial.

Throughout the article, we will explore all relevant aspects of this instrument, as well as its integration with satellite technology to achieve a thorough and highly precise analysis of ground behavior.

At Detektia, we provide advanced solutions based on InSAR, which can be effectively integrated with data from piezometers. This combination allows us to offer specialized services to monitor, for example:

What is a piezometer?

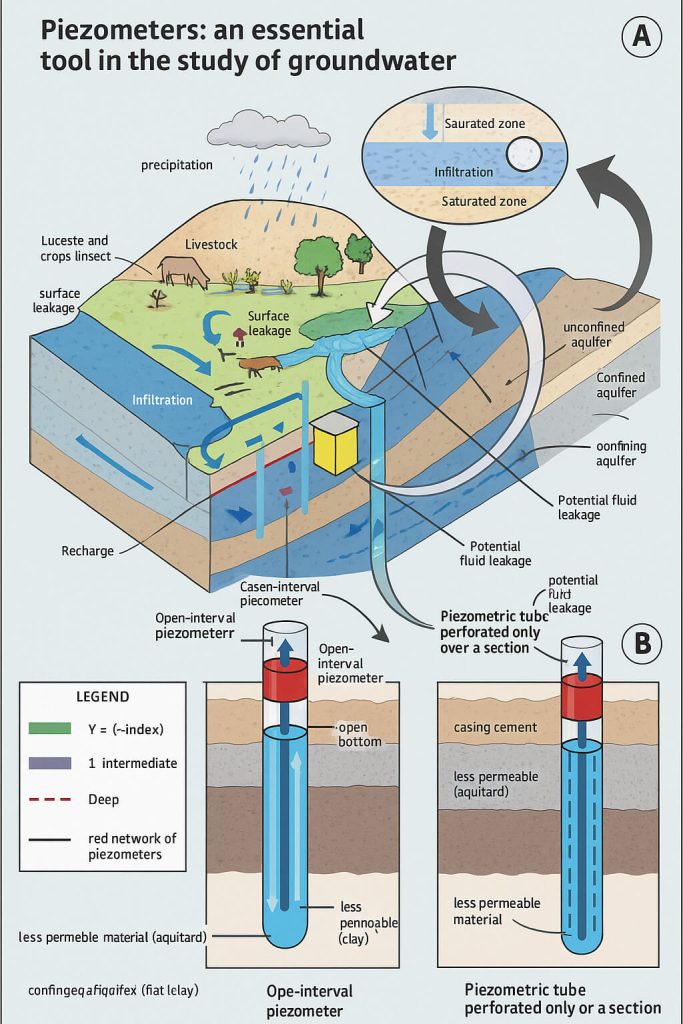

A piezometer is an instrument designed to measure water pressure in the subsurface, providing crucial data on the water table level and pore water pressure in the soil.

Piezometers are essential in hydrogeology and geotechnical engineering, as they facilitate water resource management, slope stability assessment, and risk prevention in construction projects such as dams, slopes, and landfills.

Piezometers are instruments used to measure water pressure within soil or structures, allowing the determination of the groundwater level or pore water pressure in saturated environments.

There are different types of piezometers adapted to various geological conditions and specific applications, ensuring accurate and reliable measurements.

How does a piezometer work?

El funcionamiento de un piezómetro se basa en los principios de la hidrostática, la rama de la física que estudia los líquidos en reposo y las fuerzas que ejercen. En particular, permite analizar cómo se transmite la presión en un fluido, cómo varía con la profundidad y cómo actúa sobre las superficies sumergidas.

When a piezometer is installed in an aquifer or a porous medium, water enters through small holes or filters in the tube, reaching a level that represents the water pressure at that point in the ground. This level can be observed directly or recorded using sensors, depending on the type of piezometer.

Their operation is based on recording the height at which a column of water stabilizes inside a tube installed in the ground or in a civil engineering structure. They are essential in geotechnics and hydrogeology for assessing the stability of slopes, dams, foundations, or the behavior of aquifers.

Based on these measurements, it is possible to determine the piezometric or water table level and analyze its variations over time. In addition, the filters included in many models help prevent the entry of particles that could affect the accuracy of the readings.

Why are piezometers important? Main uses and advantages

The use of piezometers is crucial because they provide key information for decision-making in engineering, environmental protection, and the sustainable management of water resources. Their continuous monitoring ensures the safety and sustainability of projects that depend on the interaction between water and soil. Below are their main applications and advantages:

- Structural stability monitoring: Measure pressure in walls, dams, and foundations.

- Water management: Track groundwater levels and flow patterns.

- Risk prevention: Detect potential ground failures.

- Design optimization: Provide essential data to improve construction projects.

- Hydrogeology: Determine the piezometric level in aquifers, essential for water supply studies.

- Geotechnics: Monitor pore water pressure, fundamental for structural stability and risk assessment.

- Pollution control: Enable groundwater sampling for contaminant analysis, critical for environmental protection.

- Infrastructure construction: Monitor groundwater levels during the execution of large civil works such as tunnels and dams.

Types of Piezometers

Piezometers are classified into different categories based on their design and purpose, each tailored for specific applications.

Open Standpipe or Casagrande Piezometer

Open standpipe piezometers, also known as Casagrande-type piezometers, are characterized by their simple and robust design. They consist of a slotted or perforated tube, usually fitted with a filter at the bottom end to prevent the entry of particles. Groundwater freely enters the tube through these openings, allowing for direct observation of the water table inside the pipe.

Their installation is relatively straightforward: a borehole is drilled to the desired depth, the tube with its filter is inserted at the base, and the surrounding space is filled with gravel or draining material to ensure adequate exchange with the environment. This type of piezometer has no moving parts, making it reliable and low-maintenance.

Casagrande-type piezometers allow for direct and uncomplicated observation. They feature a robust design, require minimal maintenance, and offer maximum reliability. They are ideal for studies on stability, drainage, and groundwater quality.

They are particularly useful in dam and reservoir stability monitoring, geotechnical slope studies, drainage system control, and environmental assessments related to groundwater quality. Although they can be affected by atmospheric pressure, their simplicity makes them an effective solution for spot measurements of groundwater levels.

Vibrating Wire Piezometer (VWP)

Vibrating wire piezometers are sophisticated instruments designed to measure pore water pressure in the ground with high precision and resolution. They operate using a sensor connected to a diaphragm that deforms under water pressure, altering the tension of a metal wire. This wire vibrates at a specific frequency, which correlates directly with the pressure applied to the diaphragm.

This operating principle allows for extremely accurate and reliable readings, even under demanding conditions. They are ideal for continuous and real-time monitoring, thanks to their compatibility with data acquisition systems and ability to transmit information remotely.

Vibrating wire piezometers (VWP) detect even the slightest variations in pore water pressure with high resolution. They provide real-time readings and remote data transmission for quick and reliable decision-making. They are perfect for foundations, dams, or tunnels where every data point matters.

VWPs are widely used in geotechnical engineering projects and critical infrastructure, where it is essential to detect changes in pore pressure quickly and accurately. Their use enables informed decision-making and helps anticipate potential ground failures, significantly increasing safety in structures such as tunnels, dams, deep foundations, and slopes.

Pneumatic piezometer

Pneumatic piezometers are instruments that use compressed gas to indirectly measure subsurface water pressure. Instead of relying on direct contact with water, this system injects gas into the piezometer tube until it balances the pressure of the surrounding groundwater. The pressure required to reach this equilibrium is then measured and correlated with the pore water pressure in the soil.

This type of piezometer is especially useful in environments where water is difficult to sample or where ground conditions involve high-pressure levels. One of its main advantages is that it eliminates the effects of water surface tension, which improves measurement accuracy in certain situations.

Pneumatic piezometers measure water pressure without direct contact. By eliminating the effects of surface tension, they provide more accurate readings in complex ground conditions. They are easy to install, deliver precise point data, and offer high durability in harsh environments.

Pneumatic piezometers are commonly used in geotechnical applications where simple installation, reliable spot measurements, and resistance to harsh environments are required.

Hydraulic piezometers

Hydraulic piezometers are designed to measure water pressure at the lower end of the device, transmitting it to the surface through thin water-filled tubes. This pressure can be recorded in real time, allowing for constant and accurate monitoring of water levels in critical structures such as dams, tunnels, or retaining walls.

They are especially useful for long-term monitoring, in situations that require frequent recalibration, or when it’s necessary to detect slight negative pressures, which other types of piezometers may not accurately capture.

Hydraulic piezometers allow for continuous and precise monitoring of the water level, detecting even slight negative pressures—crucial for long-term monitoring. In corrosive environments, titanium models ensure durability and optimal performance.

The choice of this system also depends on environmental conditions: in corrosive environments, for instance, versions made of titanium are often used to ensure durability. Moreover, their integration with InSAR technology enhances the quality and scope of subsurface behavior analysis, offering an even more comprehensive tool for geotechnical risk management.

Piezometer Installation

Although a complete piezometer installation manual would require an article of its own, we aim to summarize and highlight the key aspects of the process. First and foremost, it’s important to emphasize that proper installation is essential to ensure the accuracy and reliability of the measurements.

Installation requires careful planning that considers both ground conditions and monitoring objectives. Below are some essential aspects to take into account:

Site Selection

Choosing the location where the piezometer will be installed must be strategic. A well-selected site ensures that the data accurately reflects groundwater behavior. Key factors to consider include:

- Local geology: Analyze the soil and rock type to determine the appropriate drilling technique and piezometer type.

- Proximity to water sources: Place the piezometer near aquifers or other water-relevant areas.

- Contamination sources: Avoid areas near landfills or other zones where contaminant infiltration could alter the data.

Drilling and Placement Methods

Drilling methods are adapted to the type of soil and available resources:

- Manual drilling: Suitable for soft, shallow soils.

- Mechanical drilling: Uses machinery to drill through harder soils more efficiently.

Once the borehole is drilled, the piezometer tube is placed, ensuring that the filter is correctly oriented toward the area of interest. The borehole is typically 15–30 cm deeper than the final position of the piezometer.

Installation Techniques by Soil Type

Depending on ground characteristics, three main methods may be used:

- Sand backfill: Clean fine sand is placed around the filter and sealed with a bentonite-cement grout. Recommended for medium to hard soils.

- Upward grouting: The borehole is filled from the filter zone upward with impermeable grout. Suitable for soft soils.

- Direct injection: A mixture similar in properties to the surrounding soil is injected, useful for quick or emergency installations.

Backfill and Sealing Materials

- Backfill material: Typically sands or gravels that allow water flow while blocking unwanted particles.

- Top seal: It is essential to protect the upper end of the piezometer to prevent the entry of contaminants or sediments that could interfere with measurements.

A properly executed installation ensures longer sensor lifespan and representative subsurface behavior data.

Maintenance

Regular maintenance of piezometers is essential to ensure reliable readings over time and prolong the equipment’s lifespan.

A proper installation should be accompanied by a preventive maintenance program tailored to the environment and device type.

Reading Methods and Calibration

To obtain accurate data, an initial calibration is recommended after installation, followed by periodic checks. This includes reviewing the data acquisition system and ensuring proper signal transmission.

- Frequently check cable and terminal connections to avoid reading errors.

- In areas prone to lightning, install surge protectors such as tripolar plasma arresters or LAB-3-type plates.

Regular Maintenance Steps

- Site inspection: Conduct frequent visual inspections to identify possible disturbances. In compressible soils, it is recommended to place a marker ring at the base of the tube and measure its elevation during each reading to detect settlement or displacement.

- Interference control: To ensure stable measurements, follow these guidelines: verify system grounding, keep equipment away from electrical noise sources, and inspect the diaphragm and sensor casing for signs of damage or wear.

- Protection against harsh conditions: In saline or aggressive environments, use corrosion-resistant materials. For frost-prone areas, specific modifications exist to protect the diaphragm from low temperatures.

Integration of Piezometers with Satellite InSAR Technology

Combining piezometer data with InSAR satellite technology provides a more complete, precise, and actionable view of ground behavior. This synergy adds significant value to civil engineering, geotechnical, and water resource management projects.

While piezometers provide in-depth and point-specific measurements of groundwater pressure, InSAR offers high-resolution surface data on ground deformation, even detecting movements of just a few millimeters. Together, they enable the validation, enhancement, and enrichment of geotechnical analysis by capturing multiple dimensions of subsurface behavior.

Advantages of Integration

Integrating data from piezometers with InSAR technology creates a powerful synergy that enhances the scope, precision, and analytical capacity of geotechnical monitoring projects.

While piezometers provide in-depth, point-specific measurements of groundwater pressure, InSAR offers high-resolution surface information on ground deformations—even as small as a few millimeters.

This combination provides a three-dimensional and dynamic perspective of the subsurface, significantly improving the ability to respond to potential deformations or structural failures. It also offers a stronger and more informed decision-making framework for engineers, infrastructure managers, and water resource planners. Key advantages include:

- Comprehensive coverage: Fuses the point-specific, in-depth measurements from piezometers with the broad, surface-level coverage of InSAR.

- Complementary data: Combines pore pressure readings with surface deformation data to provide a holistic view of the geotechnical environment.

- Cross-validation and temporal analysis: Correlating both data sources helps identify seasonal patterns or anomalous events with greater certainty.

- Practical applications: Monitoring of slopes, dams, and tunnels; settlement evaluation in urban or industrial areas; analysis of subsidence due to water extraction or mining; sustainable aquifer management in agricultural zones.

- High operational precision: Current systems achieve standard deviations of just 6 mm/year in vertical displacements and 4 mm/year in east-west movements. Even in areas with subsidence greater than -15 mm/year, relative errors remain below 20%.

Data Integration Methods

- Temporal synchronization: Align time series of pore pressure and ground deformation data to identify trends or common events, such as seasonal uplift/subsidence cycles.

- Spatial analysis: Correlate areas of maximum deformation detected by InSAR with the location of piezometers to provide context to the observed phenomena.

- Integration platforms: Tools like EyeRADAR, developed by Detektia, enable real-time visualization of combined data, automated early-warning alerts, and access to historical series dating back to 1992.

The combination of in-situ data and satellite observation represents the future of geotechnical monitoring. Integrating piezometers with InSAR technology not only enhances the quality of analysis but also enables risk anticipation, resource optimization, and increased safety for critical infrastructure.

Would you like us to study your case and explore the possibilities of integrating piezometer data with the potential of satellite InSAR technology? Contact us by clicking here.